Vertical Machining Center VMC-1890

Katoloso ea tlhahisoleseling ea sehlahisoa: Letoto la setsi sa machining sa TAJANE vertical machining center ke sesebelisoa se matla sa lisebelisoa tsa mochini, tse loketseng haholo ho sebetsana le likarolo tse rarahaneng joalo ka lipoleiti, lipoleiti, hlobo le likhetla tse nyane. Letoto lena la litsi tsa machining le nka moralo oa sebopeho se otlolohileng mme o na le litšobotsi tsa ho nepahala ho holimo, ts'ebetso e phahameng, le botsitso bo phahameng.

Nakong ea ts'ebetso ea machining, letoto la TAJANE vertical machining center le hlokomela ho iketsetsa le bohlale ba mokhoa oa ho sebetsa ka mekhoa e tsoetseng pele ea ho laola le theknoloji ea ho iketsetsa. Basebelisi ba hloka feela ho kenya liparamente tse amehang ka sebopeho se bonolo sa ts'ebetso ho lemoha taolo e ikemetseng ea ts'ebetso ea ts'ebetso, ho ntlafatsa haholo katleho ea tlhahiso le ho nepahala ha ts'ebetso.

Ho phaella moo, TAJANE vertical machining center series e boetse e na le scalability e ntle le ho ikamahanya le maemo, 'me e ka etsoa le ho hlophisoa ho latela litlhoko tse fapaneng tsa ts'ebetso ho finyella litlhoko tsa basebelisi ba fapaneng. Letoto lena la litsi tsa machining li ka phethela ho sila, ho bora, ho cheka, ho tlanya, ho seha likhoele le lits'ebetso tse ling tsa ts'ebetso, 'me e sebelisoa haholo sebakeng sa sefofane, ho etsa likoloi, ho lokisa hlobo, ho etsa metjhine le likarolo tse ling.

Ka bokhutšoanyane, TAJANE vertical machining center series ke sesebelisoa se setle haholo sa ho sebetsa se nang le litšobotsi tsa ho nepahala ho phahameng, ts'ebetso e phahameng, botsitso bo phahameng, joalo-joalo, 'me e sebelisoa haholo ha ho etsoa likarolo tse sa tšoaneng tse rarahaneng. Ebang ke masimong a sefofane, ho etsa likoloi, ho lokisa hlobo kapa ho etsa mechine, TAJANE vertical machining center series e ka fa basebelisi litharollo tse ntle tsa machining.

Tšebeliso ea lihlahisoa

Setsi sa machining se otlolohileng ke sesebelisoa se matla sa sesebelisoa sa mochini se sebelisoang haholo ha ho etsoa lihlahisoa tsa 5G, likarolo tsa likoloi, likarolo tsa lebokose le likarolo tse fapaneng tsa hlobo. E na le litšobotsi tsa ho nepahala ho phahameng, ts'ebetso e phahameng le botsitso bo phahameng, 'me e ka finyella litlhoko tsa ho sebetsana le likarolo tse sa tšoaneng tse rarahaneng. Litsi tsa machining tse otlolohileng li sebetsa hantle ho lokisa likarolo tse nepahetseng tsa lihlahisoa tsa 5G, ts'ebetso ea batch ea likarolo tsa khetla, ts'ebetso ea batch ea likarolo tsa koloi, ts'ebetso e potlakileng ea likarolo tsa mabokose, le ts'ebetso ea likarolo tse fapaneng tsa hlobo. Ba ka u fa litharollo tse ntle haholo tsa ts'ebetso.

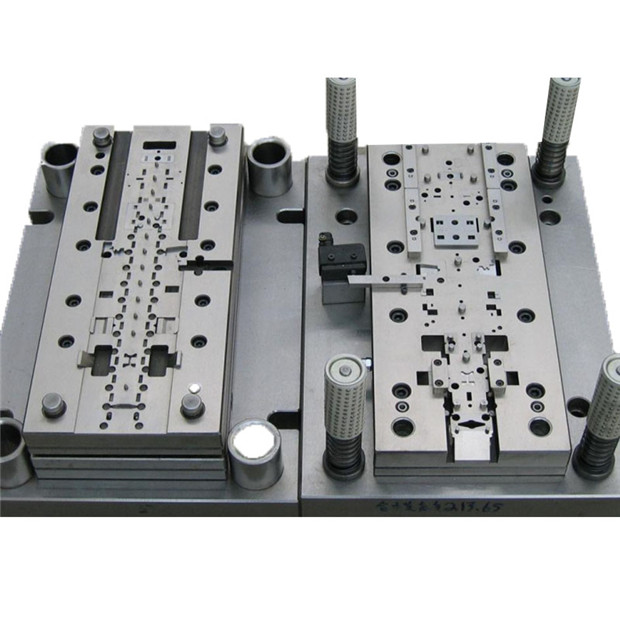

Setsi sa machining se otlolohileng, se sebelisetsoang ho etsa likarolo tse nepahetseng tsa lihlahisoa tsa 5G.

Setsi sa machining se otlolohileng se kopana le ts'ebetso ea batch ea likarolo tsa likhetla.

Setsi sa machining se emeng se khona ho hlokomela ts'ebetso ea batch ea likarolo tsa koloi.

Setsi sa machining se otlolohileng se ka khona ho etsa mochini o potlakileng haholo oa likarolo tsa lebokose.

Setsi sa machining se otlolohileng se kopana ka botlalo le ts'ebetso ea likarolo tse fapaneng tsa hlobo

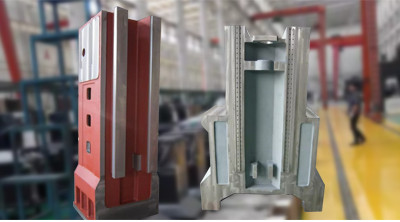

Mokhoa oa ho lahla sehlahisoa

Setsi sa machining sa CNC se amohelang mokhoa oa ho lahla Meehanite ho ntlafatsa ho hanyetsa le botsitso ba li-castings. Sebopeho sa likhopo se nang le marako a mabeli ka har'a ho lahlela se eketsa ho tiea le matla a sesebelisoa sa mochine. Lebokose la spindle le na le moralo o ntlafalitsoeng le moralo o hlakileng, o fana ka ho nepahala le ho sebetsa hantle ha mochini o phahameng. Ho hlōleha ha tlhaho ha bethe le kholomo ka katleho ho ntlafatsa ho nepahala le botsitso ba setsi sa machining. Moralo oa worktable cross slide le base o kopana le litlhoko tsa ho itšeha boima le motsamao o potlakileng, ho fa basebelisi boiphihlelo bo sebetsang hantle le bo tsitsitseng ba ts'ebetso. Setsi sa machining sa CNC vertical machining ke sesebelisoa sa ho sebetsa se nang le ts'ebetso e ntle haholo le mesebetsi e matla, e sebelisoang haholo mafapheng a fapaneng a ts'ebetso ea mochini.

CNC VMC-1890立式加工中心,铸件采用米汉纳铸造工艺.

Setsi sa machining sa CNC se otlolohileng, karolo e ka hare ea ho lahla e nka sebopeho sa likhopo tse nang le marako a mabeli.

Setsi sa machining sa CNC se otlolohileng, lebokose la spindle le amohela moralo o ntlafalitsoeng le sebopeho se loketseng.

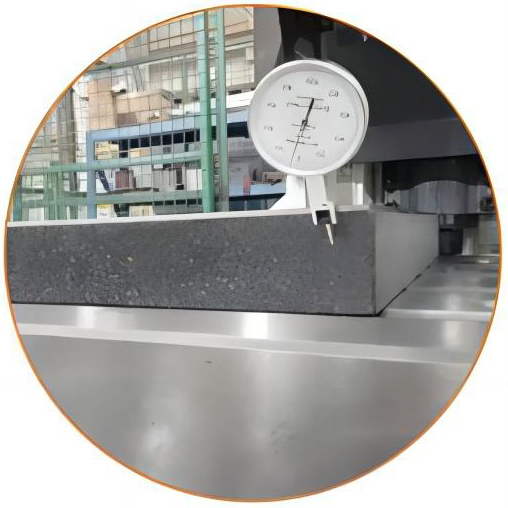

Bakeng sa litsi tsa machining tsa CNC, bethe le litšiea li hlōleha ka tlhaho, ho ntlafatsa ho nepahala ha setsi sa mochine.

CNC paatse machining setsi, tafole sefapano slide le setsi, ho kopana le boima seha le motsamao o potlakileng

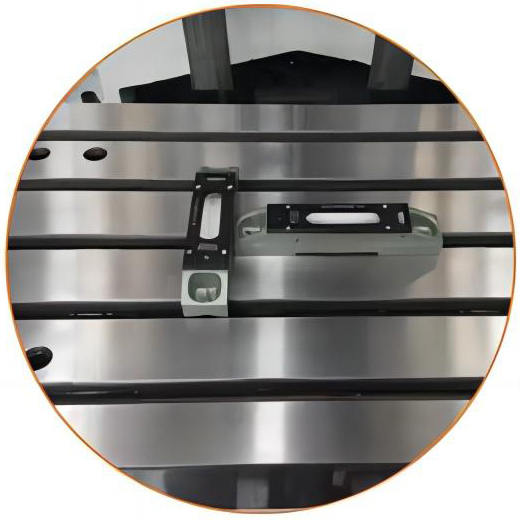

Likarolo tsa Boutique

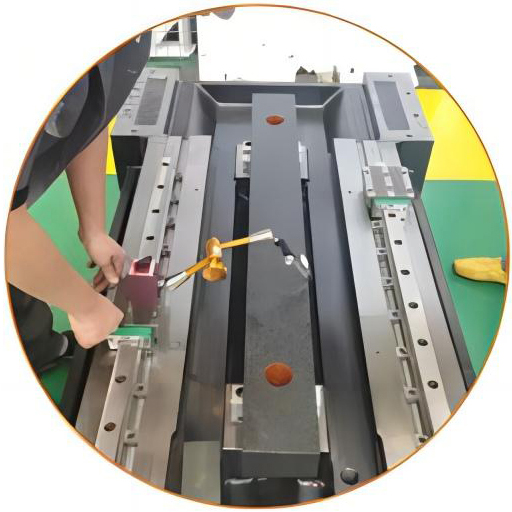

Ts'ebetso ea taolo ea tlhahlobo ea kopano e nepahetseng

Tlhahlobo ea ho nepahala ha Workbench

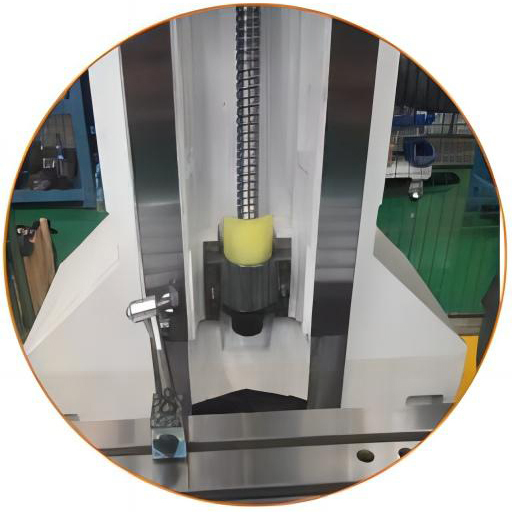

Tlhahlobo ea Karolo ea Opto-Mechanical

Ho Khetholla Bophahamo

Ho lemoha ha Parallelism

Tlhahlobo ea ho nepahala ha Setulo sa Nut

Ho Khetholla Angle Deviation

Lokisa mofuta oa CNC sistimi

TAJANE vertical machining center tools, ho ea ka litlhoko tsa bareki, e fana ka mefuta e sa tšoaneng ea mekhoa ea CNC ho finyella litlhoko tse fapaneng tsa bareki bakeng sa litsi tsa machining tse otlolohileng, FANUC, SIEMENS, MITSUBISH, SYNTEC, LNC.

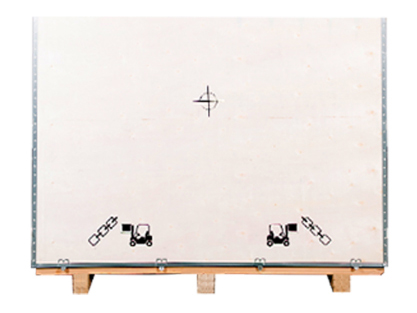

Liphutheloana tse koaletsoeng ka ho feletseng, felehetsa lipalangoang

Sephutheloana sa lehong se koetsoeng ka botlalo

Setsi sa machining sa CNC VMC-1890, sephutheloana se koetsoeng ka botlalo, se felehelitseng lipalangoang

Sephutheloana sa vacuum ka lebokoseng

CNC vertical machining center, e nang le liphutheloana tse thibelang mongobo ka har'a lebokose, tse loketseng lipalangoang tsa sebaka se selelele.

Letšoao le hlakileng

CNC vertical machining center, e nang le matšoao a hlakileng ka lebokoseng la ho paka, ho kenya le ho laolla litšoantšo, boima ba mohlala le boholo, le kananelo e phahameng.

Bracket e tiileng ea lehong

CNC vertical machining center, bokatlase ba lebokose la ho paka bo entsoe ka lehong le thata, le thata ebile le sa thelle, 'me le tiisa ho notlela thepa.

| Mohlala | Yuniti | VMC-1890 | |

| LEETO | X x Y x Z axis | mm (inch) | 1800 x 900 x 600 (70.9 x 35.5 x 23.60) |

| Spindle nko ho tafoleng | mm (inch) | 160~760 (6.3~30.0) | |

| Bohareng ba spindle ho isa holim'a kholomo e tiileng | mm (inch) | 950 (37.40) | |

| TAFOLE | Sebaka sa ho sebetsa | mm (inch) | 2000 x 900 (78.74 x 35.43) |

| Max. loading | kg | 1600 | |

| T-Slots(No. x Width x Pitch) | mm (inch) | 5 x 22 x 165 (4 x 0.7 x 6.5) | |

| SEHLOHO | Sekhahla sa lisebelisoa | - | BBT-50 |

| Lebelo | rpm | 6000 | |

| Phetiso | - | Belt Drive | |

| Ho jara lubrication | - | Tlotsa | |

| Sistimi ea ho pholisa | - | Oli e pholile | |

| Matla a spindle (a tsoelang pele / a feteletseng) | kw(HP) | 22(28.5) | |

| PHEPO LITEKO | Rapids ho X&Y&Z axis | m/m | 20/20/15 |

| Max. ho faola dijo | m/m | 10 | |

| SEBELISA MAKASINE | Bokhoni ba ho boloka lisebelisoa | likhomphutha | 24 letsoho |

| Mofuta oa sesebelisoa (boikhethelo) | mofuta | BT50 | |

| Max. bophara ba sesebelisoa | mm (inch) | 125 (4.92)letsoho | |

| Max. boima ba sesebelisoa | kg | 15 | |

| Max. bolelele ba sesebelisoa | mm (inch) | 400 (15.75) letsoho | |

| AVG.CHANGING TIME(ARM) | Sesebelisoa ho sesebelisoa | mots. | 3.5 |

| Ho hlokahala mohloli oa moea | kg/cm² | 6.5 holimo | |

| PHOMOLO | Ho beha maemo | mm (inch) | ±0.005/300 (±0.0002/11.81) |

| Pheta-pheta | mm (inch) | 0.006 bolelele bo felletseng (0.000236) | |

| TŠEBELETSO | Boima ba mochini(Net) | kg | 13000 |

| Ho hlokahala mohloli oa matla | KVA | 45 | |

| Sebaka sa fatše (LxWxH) | mm (inch) | 4950 x 3400 x 3300 (195 x 133 x 130) |

Lisebelisoa tse tloaelehileng

●Molaoli oa Mitsubishi M80

●Spindle lebelo 8,000 / 10,000 rpm(ho itshetlehile ka mofuta wa mochini)

●Mofetoleli oa sesebelisoa o iketselitseng

● Ho sireletsa ka ho feletseng

● Mocheso oa mocheso bakeng sa khabinete ea motlakase

● Automatic lubricating system

● Pholisa oli ea spindle

●Spindle air blast system (M khoutu)

● Ho sekamela ha spindle

●Sethunya se pholileng le sokete ea moea

● Lisebelisuoa tsa ho tsitsa

● Removable manual & pulse generator (MPG)

● Leseli la LED

● Ho otla ka thata

● Sistimi e pholileng le tanka

● Pontšo ea ho qetela ea potoloho le mabone a alamo

● Lebokose la Lisebelisoa

● Buka ea ho sebetsa le ea tlhokomelo

● Transformer

● Spindle coolant rining(M code)

Lisebelisoa tsa boikhethelo

●Spindle speed 10,000 rpm (Mofuta o tobileng)

● Coolant through spindle (CTS)

● Sesebelisoa sa ho lekanya bolelele ba sesebelisoa se iketselitseng

● Mokhoa o itekanetseng oa ho lekanya karolo ea mosebetsi

● Tafole ea rotary ea CNC le tailstock

● Motho ea thellang oli

● Kopanya mofuta oa chip conveyor le chip bakete

●Litekanyo tsa mola (X/Y/Z axis)

● Ho pholile ka ho sebelisa sesebelisoa