Setsi sa machining se otlolohileng VMC-1100

Morero

TAJANE vertical machining center VMC-1100 series e etselitsoe ka ho khetheha ho sebetsana le likarolo tse rarahaneng tse kang lipoleiti tsa tšepe, likarolo tse bōpehileng joaloka disc, hlobo le matlo a manyenyane. Setsi sa machining se otlolohileng se ka etsa ts'ebetso ka mokhoa o phethahetseng joalo ka ho sila, ho bora, ho cheka, ho tlanya le ho seha likhoele, ho fana ka tharollo bakeng sa ts'ebetso ea likarolo tsa tšepe libakeng tse fapaneng.

Tšebeliso ea Sehlahisoa

TAJANE vertical machining center VMC-1100 series e ka sebelisoa ho sebetsana le likarolo tse nepahetseng tsa lihlahisoa tsa 5G, hape e ka finyella litlhoko tsa ts'ebetso ea likarolo tsa khetla, likarolo tsa likoloi le likarolo tse sa tšoaneng tsa hlobo. Ntle le moo, e ka hlokomela ts'ebetso e potlakileng ea likarolo tsa mofuta oa mabokose, ho ntlafatsa ts'ebetso ea ts'ebetso le ho nepahala ha ts'ebetso.

Vertical machining center 5G likarolo tse nepahetseng tsa ho sebetsa

Setsi sa machining se otlolohileng bakeng sa ts'ebetso ea batch ea likarolo tsa khetla

Setsi sa machining se otlolohileng bakeng sa ho sebetsa likarolo tsa likoloi

Setsi sa machining se otlolohileng bakeng sa ts'ebetso ea likarolo tsa mofuta oa lebokose

Setsi sa machining se otlolohileng bakeng sa ho sebetsa likarolo tsa hlobo

Mokhoa oa ho lahla sehlahisoa

Bakeng sa letoto la CNC VMC-1100 vertical machining center, li-castings li amohela mokhoa oa ho lahla oa Meehanite ka sehlopha sa TH300, se nang le matla a phahameng le khanyetso e phahameng ea ho apara. Hare-hare ho castings ea VMC-1100 paatsepama machining setsi se entsoe ka habeli lebota keriti-joaloka likhopo sebopeho.Ho phaella moo, phekolo ea tlhaho ea botsofali ba bethe le kholomo ea setsi sa machining sa VMC-1100 se ntlafatsa ka katleho ho nepahala ha setsi sa machining. The worktable sefapano slide le botlaaseng ka kopana ditlhoko tsa ho itšeha boima le motsamao o potlakileng, ho fana ka basebedisi ba le ho feta sebetsang hantle le e tsitsitseng ho sebetsana le phihlelo.

Mokhoa oa ho fokotsa sekhahla se sa lumellaneng sa

meaho ea setsi sa mochini o otlolohileng ho fihla ho 0.3%

Setsi sa machining sa CNC se otlolohileng, se nang le likhopo tse nang le marako a mabeli ka har'a sethala.

Setsi sa machining sa CNC se otlolohileng, lebokose la spindle le amohela moralo o ntlafalitsoeng le sebopeho se loketseng.

Bethe le kholomo ea setsi sa machining e tsofala ka tlhaho bakeng sa ho nepahala ho holimo.

CNC paatse machining setsi, tafole sefapano slide le setsi, ho kopana le boima seha le motsamao o potlakileng

Mokhoa oa ho kopanya lihlahisoa

Setsing sa mochini o otlolohileng sa VMC-1100, botsitso ba ho nepahala le ho tiea ha sesebelisoa sa mochini ho matlafatsoa ka ho hoholoa ha libaka tse hokahaneng tsa likarolo tse joalo ka setulo sa ho jara, libaka tse hokahaneng tsa setulo sa linate tse ka sebetsoang le slide, sebaka sa ho ikopanya lipakeng tsa lebokose la spindle le spindle, le libaka tse hokahaneng tsa setsi le kholomo. Ka nako e ts'oanang, e felisa khatello ea kelello ka har'a sesebelisoa sa mochine, e fokotsa likhohlano, 'me e lelefatsa bophelo ba tšebeletso ea setsi sa machining se otlolohileng.

Ho nepahala ha setsi sa machining se emeng se "hlakotsoe" joang?

① Ho phunya le ho phunya setulo se behileng sa setsi sa mochini se otlolohileng

② Ho phunya le ho qhoqhoa ha libaka tsa ho kopana pakeng tsa setulo sa linate tse sebetsang hantle le slide.

③ Sebaka sa ho kopana pakeng tsa hlooho ea hlooho le mokokotlo oa setsi sa machining se otlolohileng

④ Ho hula le ho phunya sebaka sa ho kopana pakeng tsa motheo le kholomo

Mokhoa oa ho hlahloba ho nepahala

Lihlahisoa tsohle tsa CNC VMC-1100 vertical machining center li etsa liteko tsa tlhahlobo e nepahetseng pele li tloha fekthering. Tsena li kenyelletsa tlhahlobo ea ho nepahala ha jiometri, tlhahlobo ea ho nepahala ha maemo, tlhahlobo ea ho nepahala ea ho itšeha, le tlhahlobo ea ho nepahala ha laser interferometer. Mohato o mong le o mong o hloka litekanyo tse ngata ho bala boleng ba karolelano, e le ho fokotsa liphoso tse sa lebelloang, ho netefatsa liphetho, le ho finyella liphello tsa machining tsa lebelo le phahameng, tse nepahetseng, le tse sebetsang hantle haholo.

Tlhahlobo ea ho nepahala ha Workbench

Tlhahlobo ea opto-mechanical

Ho Khetholla Bophahamo

Ho lemoha ha Parallelism

Tlhahlobo ea ho nepahala ha Setulo sa Nut

Ho Khetholla Angle Deviation

Likarolo tsa moralo

Likarolo tsa mantlha tsa 'mele oa sesebelisoa sa mochini bakeng sa litsi tsa machining tse otlolohileng tsa VMC-1100 li entsoe ka tšepe e matla e phahameng ea HT300, e fuoa kalafo ea mocheso, botsofali ba tlhaho le ts'ebetso e nepahetseng ea serame. E nka kholomo ea herringbone, e nang le mochini o hanyetsanang le boima ba Z-axis. Litšepe tsa tataiso li hlakoa ka letsoho, li matlafatsa ho tiea le ho qoba ho sisinyeha ha mechine.

Video ea lits'oants'o tse otlolohileng tsa setsi sa machining

Mochini o bobebe oa setsi sa machining

Setsi sa machining se otlolohileng se Bearing Spindle

Setsi sa machining se otlolohileng Bearing

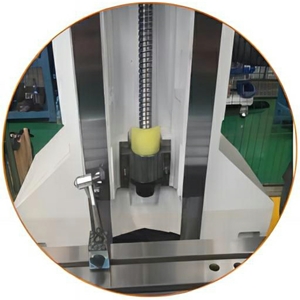

Setsi sa machining sa CNC se otlolohileng, sekoti sa lead

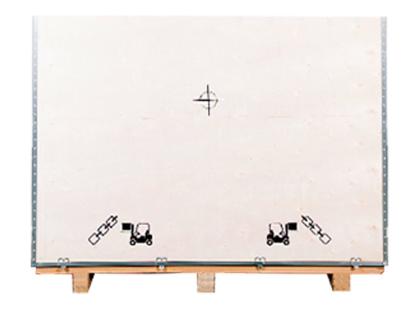

Sephutheloana se Matla

Letoto lohle la litsi tsa mochini tse otlolohileng tsa CNC VMC-1100 li kentsoe ka har'a mekotla ea lepolanka e koetsoeng ka botlalo, e nang le liphutheloana tse thibelang mongobo kahare ho mekotla. Li loketse lipalangoang tsa maeto a malelele joalo ka lipalangoang tsa mobu le leoatle. Setsi se seng le se seng sa machining se emeng se ka romelloa ka mokhoa o sireletsehileng le ka nako ho ea libakeng tsohle tsa lefats'e.

Khokahano ea ho notlela, e tiile ebile e tsitsitse.

Ho romelloa mahala ho likoung tse kholo le likoung tse fanang ka tumello ea lekhetho naheng ka bophara.

Ho tloswa ha matshwao

Khokahano ea ho notlela

Lehong le tiileng la bohareng

Sephutheloana sa vacuum

Lisebelisoa tse tloaelehileng

Tlhophiso e tloaelehileng ea letoto le felletseng la VMC-850 Vertical Machining Centers ke senotlolo sa ho netefatsa ts'ebetso e tsitsitseng ea mesebetsi ea mantlha ea machining. E theha litiiso tse tsoang likarolong tse tharo tsa mantlha: ts'ireletso ea polokeho, ts'ebetso e tšepahalang le ts'ebetso e bonolo. E loketse ho finyella litlhoko tsa mekhoa e tloaelehileng ea ho itšeha tšepe 'me e rala motheo oa katleho ea tlhahiso le boleng ba machining.

Lisebelisoa tse eketsehileng

I. Bakeng sa mefuta e felletseng ea litsi tsa machining tsa VMC-850 tse otlolohileng, li-spindle tsa boikhethelo lia fumaneha e le lisebelisoa tse ling:

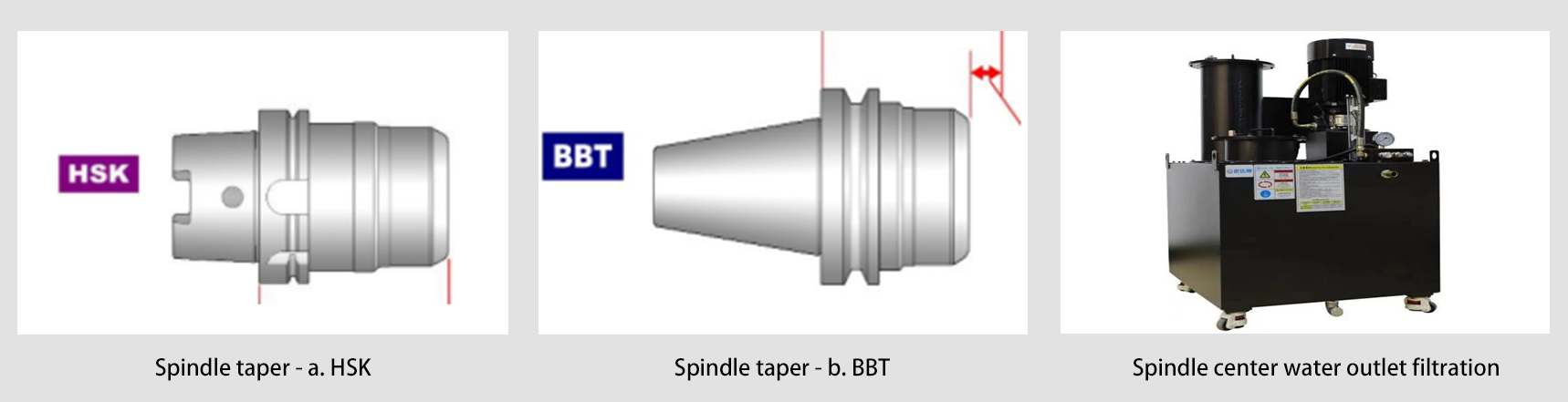

II. Bakeng sa mefuta e felletseng ea litsi tsa mochini tse otlolohileng tsa VMC-850, mefuta ea "spindle taper" le "spindle center water filtration" li fumaneha joalo ka lisebelisoa tse ling:

III. Bakeng sa mefuta e felletseng ea litsi tsa mochini tse otlolohileng tsa VMC-850, sesebelisoa sa boikhethelo se fumaneha e le lisebelisoa tse ling:

IV. Bakeng sa mefuta e felletseng ea litsi tsa machining tsa VMC-850 tse otlolohileng, litekanyo tsa boikhethelo tsa mela le lisebelisoa tse lekanyang OMP60 lia fumaneha e le lisebelisoa tse eketsehileng:

V. Bakeng sa mefuta e felletseng ea litsi tsa machining tsa VMC-850 tse otlolohileng, makasine ea boikhethelo ea lisebelisoa e teng e le lisebelisoa tse ling:

VI. Bakeng sa mefuta e felletseng ea litsi tsa mochini tse otlolohileng tsa VMC-850, likarohano tse bonolo tsa metsi a oli le likoleke tsa moholi oa oli lia fumaneha e le lisebelisoa tse ling:

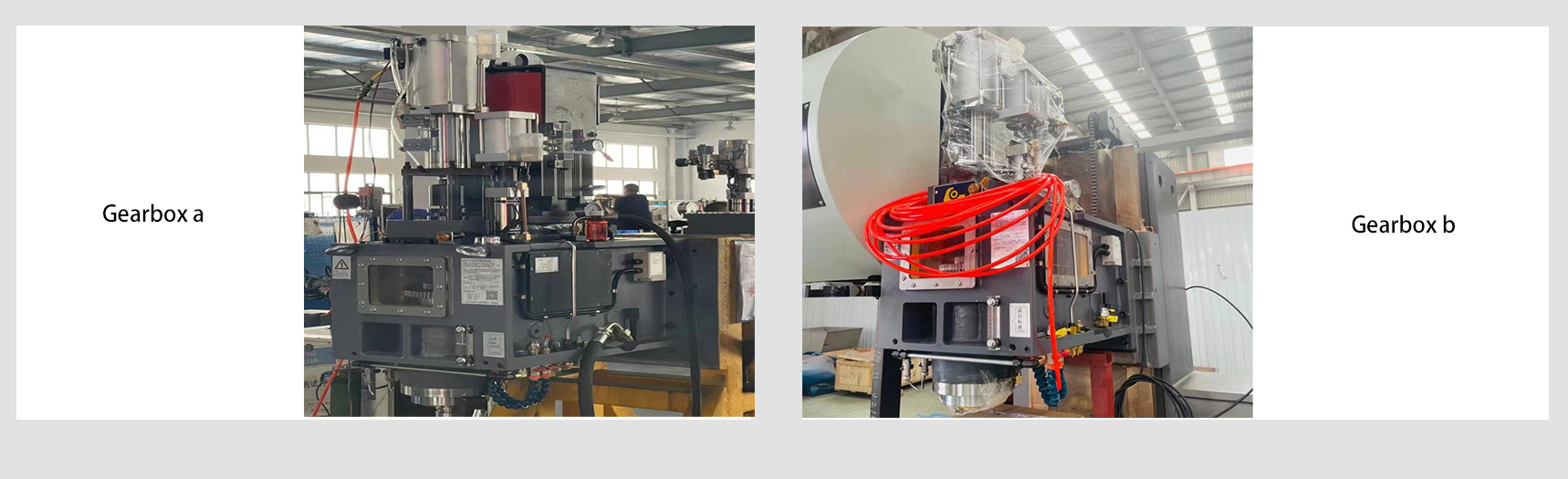

VII. Bakeng sa mefuta e felletseng ea litsi tsa mochini tse otlolohileng tsa VMC-850, lebokose la gear la boikhethelo le fumaneha joalo ka lisebelisoa tse ling:

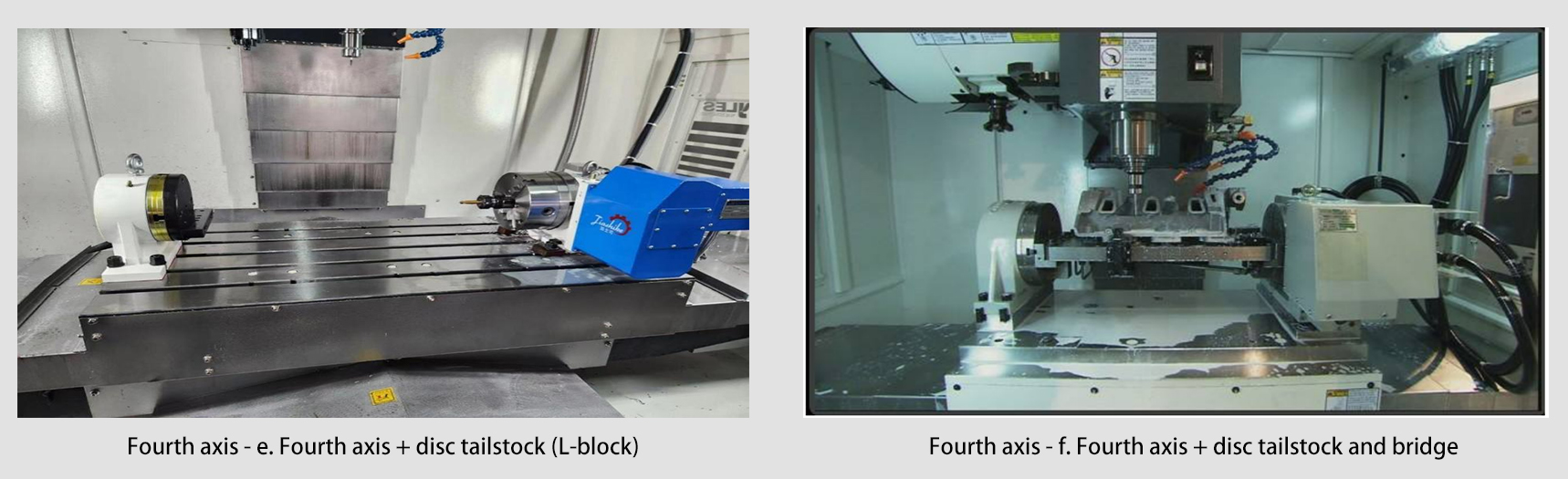

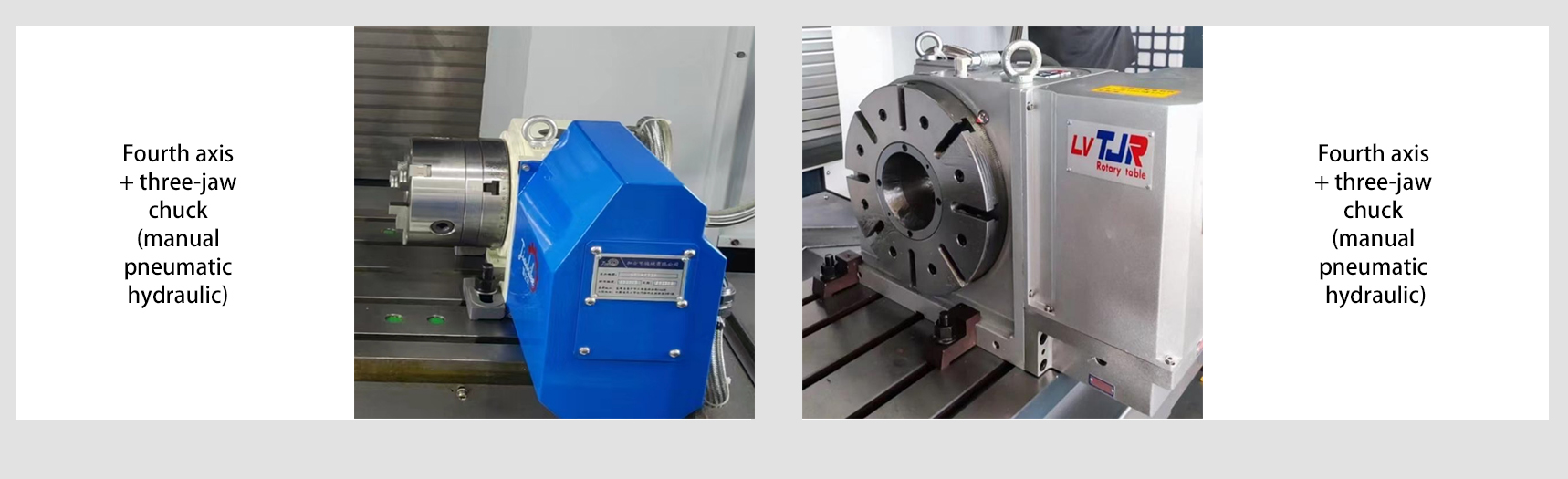

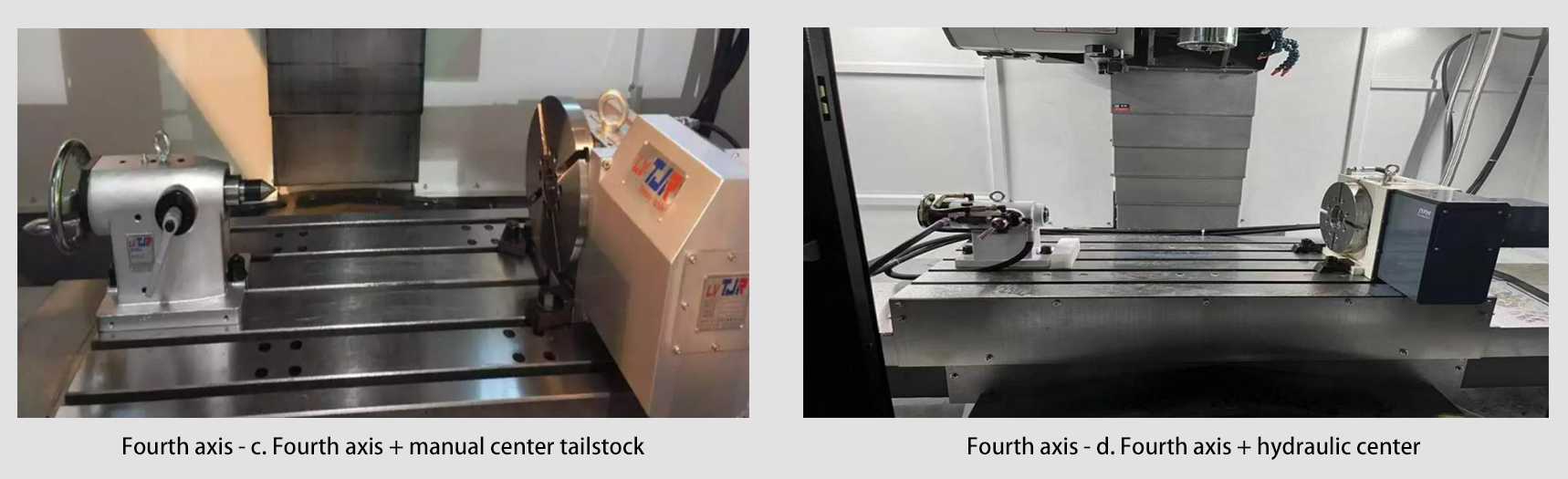

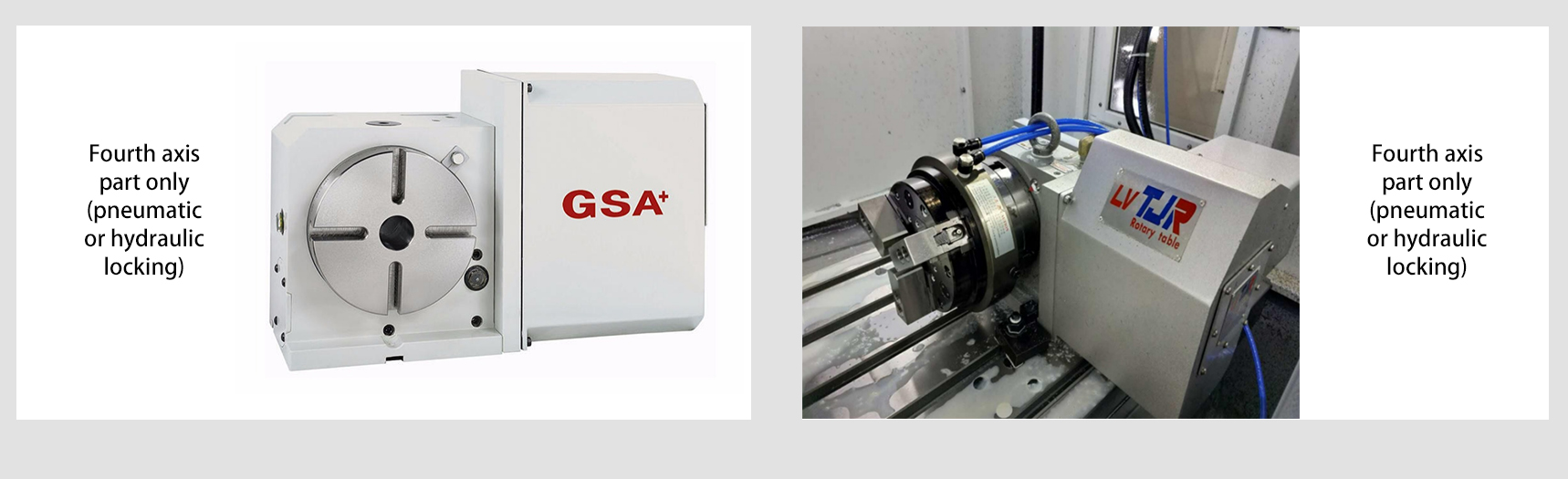

VIII. Bakeng sa mefuta e felletseng ea litsi tsa machining tsa VMC-850, ho na le axis ea bone ea boikhethelo e fumanehang e le lisebelisoa tse ling:

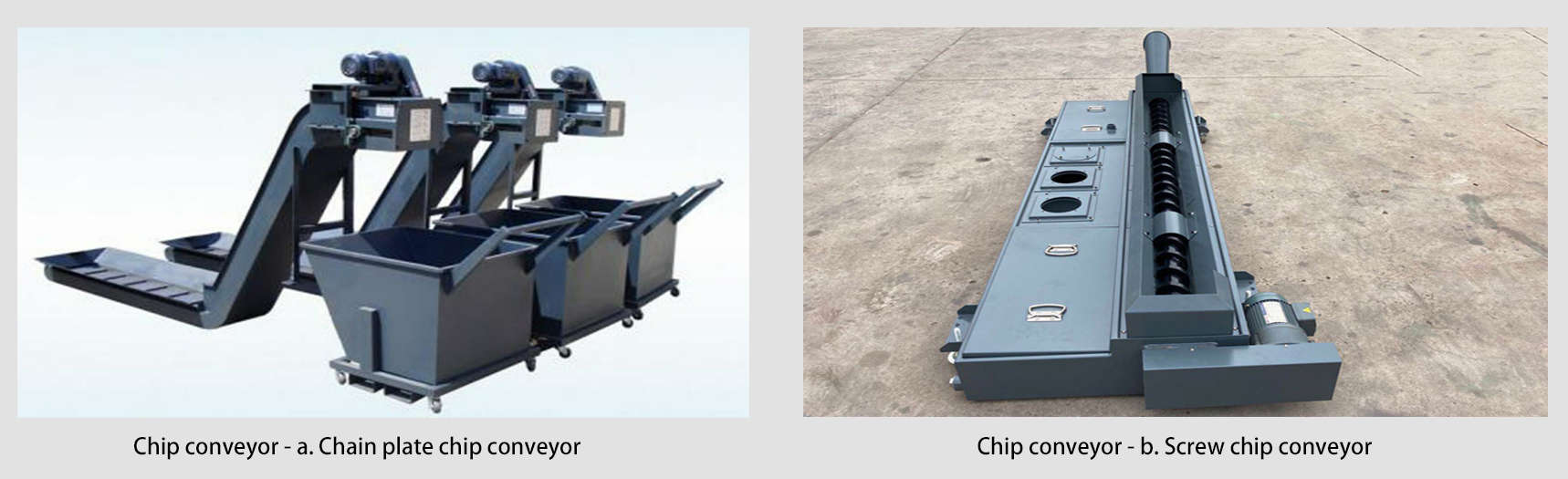

IX. Bakeng sa mefuta e felletseng ea litsi tsa mochini tse otlolohileng tsa VMC-850, mochini o tsamaisang chip oa boikhethelo oa fumaneha e le lisebelisoa tse ling:

X. Bakeng sa mefuta e felletseng ea litsi tsa machining tsa VMC-850 tse otlolohileng, ho na le axis ea bohlano e fumanehang e le lisebelisoa tse ling:

| Mohlala | VMC-1100A (Litsela tse tharo tsa Linear Guideways) | VMC-1100B (Tse peli Linear le One Hard) | VMC-1100C (Litsela tse tharo tse thata) |

|---|---|---|---|

| Spindle | |||

| Spindle Taper | BT40 | BT40 | BT40 |

| Lebelo la Spindle (rpm/min) | 8000 (Ho khanna ka kotloloho 15,000 rpm, boikhethelo) | 8000 (Ho khanna ka kotloloho 15,000 rpm, boikhethelo) | 8000 (Ho khanna ka kotloloho 15,000 rpm, boikhethelo) |

| Main Drive Motor Power | 11kw | 11kw | 11kw |

| Matla a Phepelo ea Matla | 20 | 20 | 20 |

| Sebaka sa tšebetso | |||

| Maeto a X-axis | 1100mm | 1100mm | 1100mm |

| Leeto la Y-axis | 650 limilimithara | 650 limilimithara | 600 limilimithara |

| Leeto la Z-axis | 750 limilimithara | 750 limilimithara | 600 limilimithara |

| Boholo bo sebetsang | 650X1200mm | 650X1200mm | 600X1300mm |

| Boholo Mojaro oa Worktable | 800kg | 800kg | 800kg |

| Workbench T-slots (bongata - boholo * sebaka) | 5-18*90 | 5-18*90 | 5-18*90 |

| Sebaka se pakeng tsa axis ea spindle le kholomo | 690 limilimithara | 660 limilimithara | |

| Sebaka ho tloha sefahlehong sa spindle ho ea ho workbench | 110-860 limilimithara | 110-860 limilimithara | |

| Lisebelisoa tsa ho sebetsa | |||

| Tsamaea ka potlako ka lilepe tsa X/Y/Z, limithara ka motsotso | 24/24/24 | 24/24/15 | 15/15/15 |

| Lijo tse sebetsang, limilimithara ka motsotso | 1-10000 | 1-10000 | 1-10000 |

| Mokhoa oa ho laola lipalo | |||

| FANUC MF3B | X-axis: βiSc12/3000-B Y-axis: βiSc12/3000-B Z-axis: βis22/3000B-B Spindle: βiI 8/12000-B | X-axis: βiSc12/3000-B Y-axis: βiSc12/3000-B Z-axis: βis22/3000B-B Spindle: βiI 8/12000-B | X-axis: βiSc22/2000-B Y-axis: βiSc12/2000-B Z-axis: βis22/2000-B Spindle: βiI 12/10000-B |

| SIEMENS 828D | X-axis:1FK2306-4AC01-0MB0 Y-axis:1FK2306-4AC01-0MB0 Z-axis: 1FK2208-4AC11-0MB0 Spindle: 1PH3105-1DG02-0KA0 | X-axis:1FK2306-4AC01-0MB0 Y-axis:1FK2306-4AC01-0MB0 Z-axis:1FK2208-4AC11-0MB0 Spindle:1PH3105-1DG02-0KA0 | X-axis:1FK2308-4AB01-0MB0 Y-axis:1FK2308-4AB01-0MB0 Z-axis:1FK2208-4AC11-0MB0 Spindle:1PH3131-1DF02-0KA0 |

| Mitsubishi M80B | X-axis: HG204S-D48 Y-axis: HG204S-D48 Z-axis:HG303BS-D48 Spindle: SJ-DG7.5/120 | X-axis:HG204S-D48 Y-axis:HG204S-D48 Z-axis:HG303BS-D48 Spindle: SJ-DG7.5/120 | X-axis:HG303S-D48 Y-axis:HG303S-D48 Z-axis:HG303BS-D48 Spindle: SJ-DG11/120 |

| Sistimi ea lisebelisoa | |||

| Mofuta oa Makasine ea Sesebelisoa le Bokhoni | Mofuta oa disc (mofuta oa manipulator) likotoana tse 24 | Mofuta oa disc (mofuta oa manipulator) likotoana tse 24 | Mofuta oa disc (mofuta oa manipulator) likotoana tse 24 |

| Mofuta oa Sesebelisoa | BT40 | BT40 | BT40 |

| Maximum Tool Diameter / Ajacent Empty Position | Φ80/Φ150mm | Φ80/Φ150mm | Φ80/Φ150mm |

| Boholo Bolelele ba Sesebelisoa | 300mm | 300mm | 300mm |

| Maximum Tool Weight | 8kg | 8kg | 8kg |

| Ho nepahala | |||

| Pheta-pheta ea lilepe tsa X/Y/Z | 0.008mm | 0.008mm | 0.008mm |

| Boemo ba ho Nepaha ha Lilepe tsa X/Y/Z | 0.006 limilimithara | 0.006 limilimithara | 0.006 limilimithara |

| Mofuta oa Tataiso ea Axis ea X/Y/Z | Linear guide X-axis: 35 Y-axis: 45 Z-axis: 45 | Tataiso ea mola + Tataiso e thata X-axis: 45 Y-axis: 45 Z-axis: Tataiso e thata | Tsela e thata |

| Tlhaloso ea Screw | 4016/4016/4016 | 4012/4012/4012 | 4010/4010/4010 |

| Karolo | |||

| Bolelele | 2600 limilimithara | 2600 limilimithara | 2600 limilimithara |

| Bophara | 2880 limilimithara | 2500 limilimithara | 2500 limilimithara |

| Bophahamo | 2750 limilimithara | 2650 limilimithara | 2650 limilimithara |

| Boima ba 'mele | 7500kg | 7800kg | 7500kg |

| Khatello ea Moea e Hlokehang | ≥0.6MPa ≥500L/min(ANR) | ≥0.6MPa ≥500L/min(ANR) | ≥0.6MPa ≥500L/min(ANR) |

TAJANE Setsi sa Tšebeletso

TAJANE e na le setsi sa tšebeletso sa lisebelisoa tsa mochini oa CNC Moscow. Litsebi tsa lits'ebeletso li tla u thusa ho tataisa ho kenya, ho lokisa, ho hlahloba lisebelisoa, tlhokomelo, le koetliso ea ts'ebetso ea lisebelisoa tsa mochine oa CNC. Setsi sa tšebeletso se na le polokelo ea nako e telele ea lisebelisoa le lisebelisoa bakeng sa mefuta eohle ea lihlahisoa.