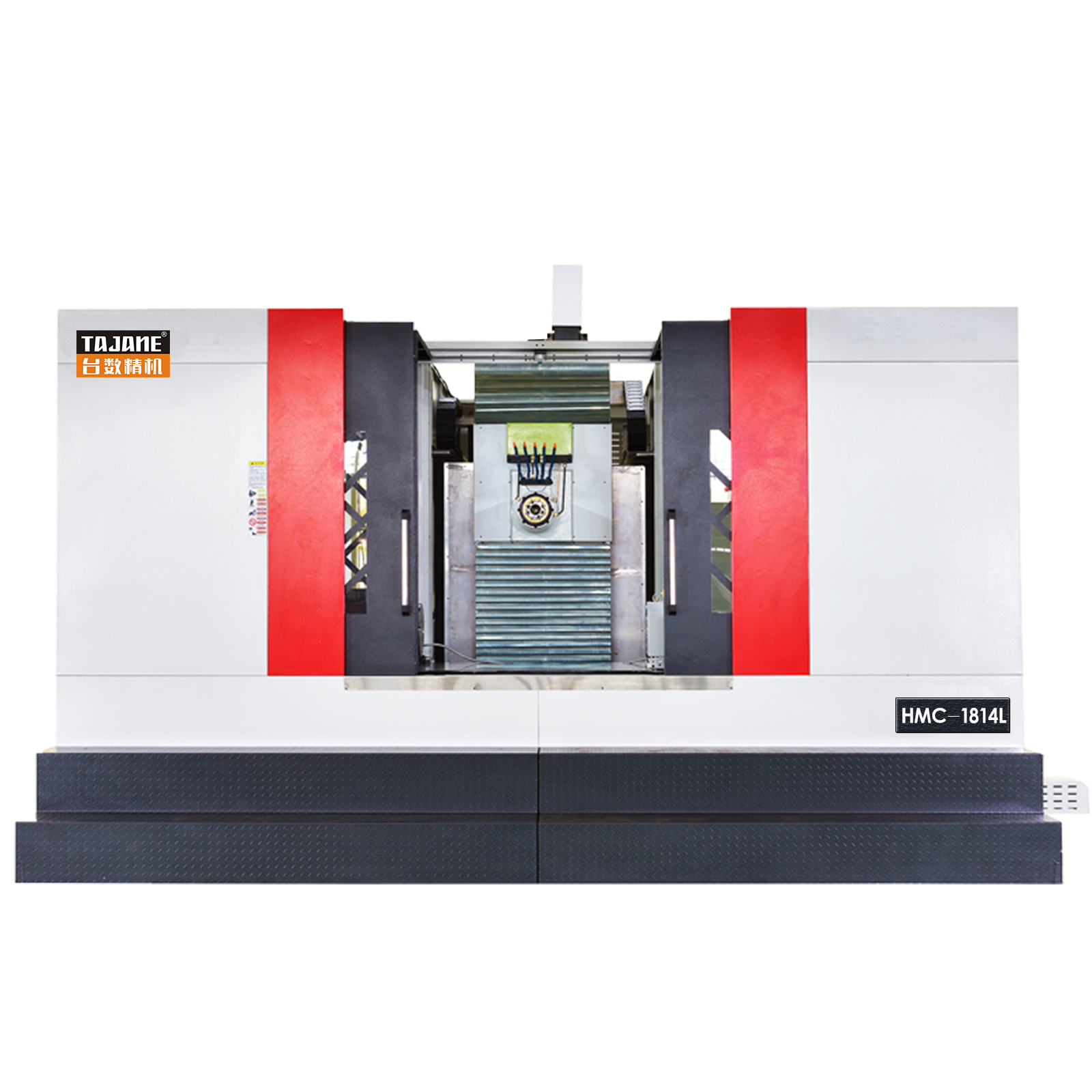

Horizontal Machining Center HMC-1814L

Setsi sa machining sa Qingdao Taizheng ke khetho ea hau e nepahetseng bakeng sa machining a nepahetseng. Letoto la rona la TAJANE vertical machining center le etselitsoe ka ho khetheha ho sebetsana le likarolo tse rarahaneng tse kang lipoleiti, lipoleiti, hlobo le likhetla tse nyane. Litsi tsa machining tse otlolohileng li etsa tšebetso e phethahetseng joalo ka ho sila, ho bora, ho phunya, ho tlanya le ho seha likhoele.

Melemo e ikhethang ea lihlahisoa tsa rona ke ho nepahala ho phahameng le lebelo la ho sebetsa ka potlako. Ka thekenoloji e tsoetseng pele le moralo o hlokolosi, litsi tsa machining tseo re fanang ka tsona li ka phethahatsa litlhoko tsa ho sebetsana le likarolo leha e le life tse rarahaneng ka ho nepahala ho babatsehang. Ebang ke lintlha tse nyane kapa libopeho tse rarahaneng, lihlahisoa tsa rona li ka tsosolosoa hantle 'me tsa netefatsa hore mohato o mong le o mong oa ho sebetsa o nepahetse.

Tšebeliso ea lihlahisoa

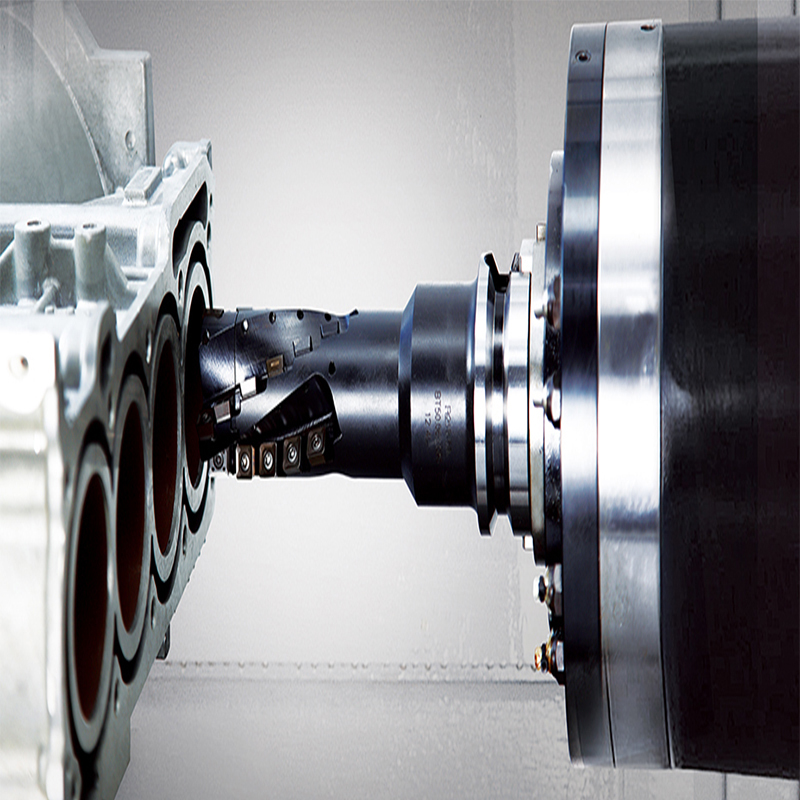

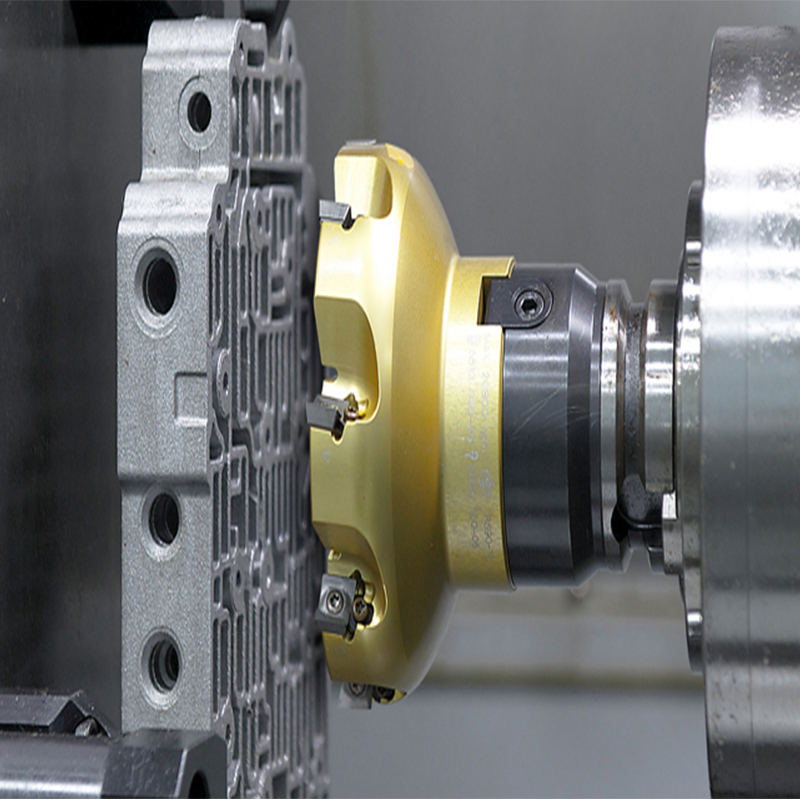

Setsi sa machining se otlolohileng ke lisebelisoa tse sebetsang hantle le tse nepahetseng tse sebelisoang haholo likarolong tse sebetsanang le likarolo tse fapaneng. E ke ke ea sebelisoa feela ho sebetsana le likarolo tse nepahetseng tsa lihlahisoa tsa 5G, empa hape e ka finyella litlhoko tsa ho sebetsana le likarolo tsa likhetla, likarolo tsa likoloi le likarolo tse sa tšoaneng tsa hlobo. Haholo-holo ha ho tluoa tabeng ea ho etsa machining, litsi tsa machining tse otlolohileng lia ipabola, li nolofalletsa ho sebetsa ka mokhoa o sebetsang hantle, o phahameng haholo. Ntle le moo, lisebelisoa tsena li ka boela tsa hlokomela ts'ebetso e potlakileng ea likarolo tsa lebokose, ho ntlafatsa ts'ebetso ea ts'ebetso le ho nepahala ha ts'ebetso. Ka bokhutšoanyane, setsi sa machining se otlolohileng ke sesebelisoa se setle haholo sa ts'ebetso se fanang ka tharollo e ntle haholo bakeng sa ts'ebetso ea likarolo likarolong tse fapaneng.

Setsi sa machining se otlolohileng, se sebelisoang haholo ho likoloi, sefofane, mechini e akaretsang le liindasteri tse ling.

Horizontal machining setsi. Ka ho fetisisa e loketseng ho sebetsana le lichapo tse kholo le likarolo tse rarahaneng tse nepahetseng

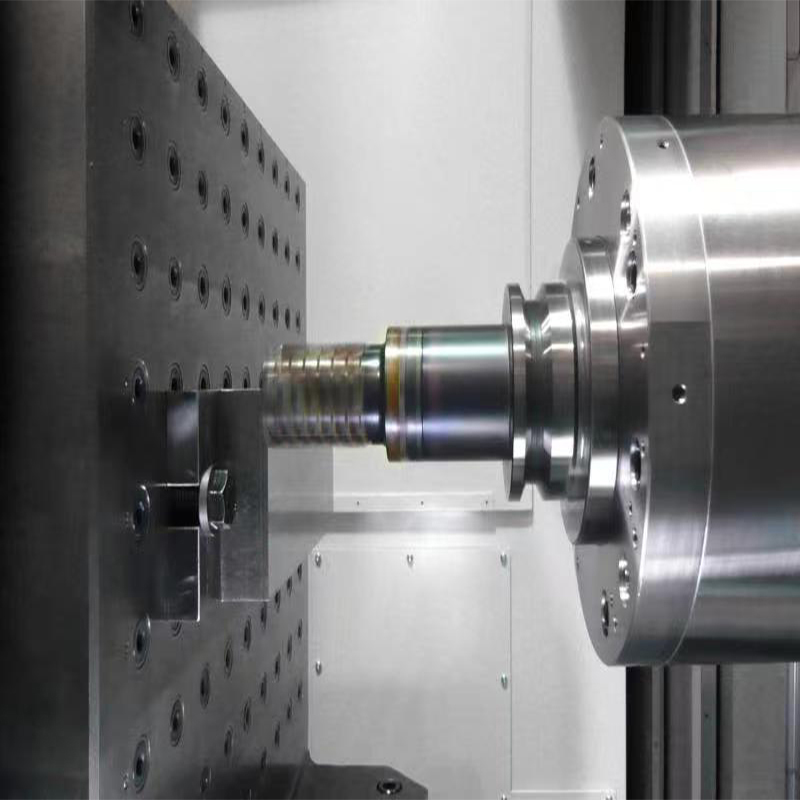

Setsi sa machining se otlolohileng, se loketseng ho sebetsa ka holim'a metsi a mangata le ho sebetsana le likarolo tse ngata

Horizontal machining litsi li sebelisoa haholo likarolong tse rarahaneng. Ho sebetsa ka holim'a metsi le lesoba.

Horizontal machining litsi li sebelisoa haholo likarolong tse rarahaneng. Ho sebetsa ka holim'a metsi le lesoba.

Mokhoa oa ho lahla sehlahisoa

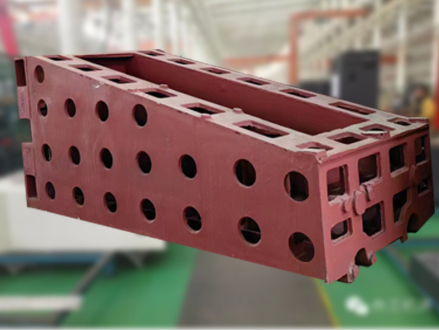

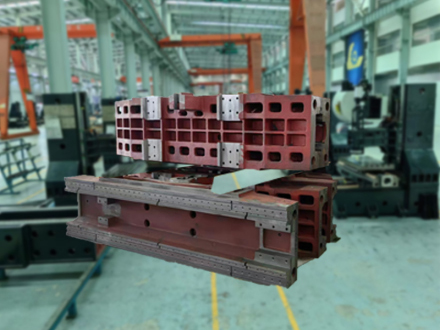

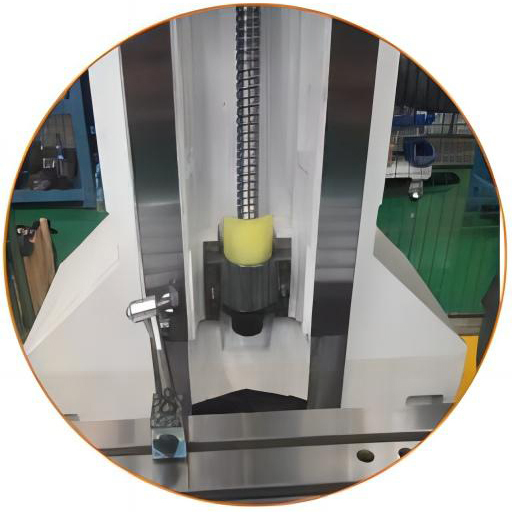

The castings ea CNC VMC-855 vertical machining center e amohela Meehanner casting process, grade TH300, e nang le matla a phahameng le khanyetso e phahameng ea ho roala. Setsi sa machining se amohela sebopeho sa likhopo tse nang le marako a mabeli ka har'a sethala, 'me lebokose la spindle le nka moralo o ntlafalitsoeng le sebopeho se hlakileng, se ka fanang ka ho nepahala le ho sebetsa hantle ha machining. Ho phaella moo, moralo oa tlhaho oa ho hlōleha ha bethe le kholomo ka katleho e ntlafatsa ho nepahala ha setsi sa machining. The worktable cross slide le base li kopana le litlhoko tsa ho itšeha boima le motsamao o potlakileng, ho fa basebelisi boiphihlelo bo sebetsang hantle le bo tsitsitseng ba ho sebetsa.

Setsi sa machining sa CNC Horizontal, ho lahla ho amohela mokhoa oa ho lahla Meehanite, 'me label ke TH300.

Mochini o otlolohileng oa ho sila, li-slide tsa tafole le setsi, ho kopana le ho itšeha ho boima le motsamao o potlakileng

Mochini o otlolohileng oa ho sila, karolo e ka hare ea ho lahla e amohela sebopeho sa likhopo tse nang le marako a mabeli.

Mochini o otlolohileng oa ho sila, bethe le litšiea li hlōleha ka tlhaho, li ntlafatsa ho nepahala ha setsi sa machining.

Setsi sa machining se otlolohileng, moralo o ntlafalitsoeng oa li-casting tse hlano tse kholo, sebopeho se loketseng

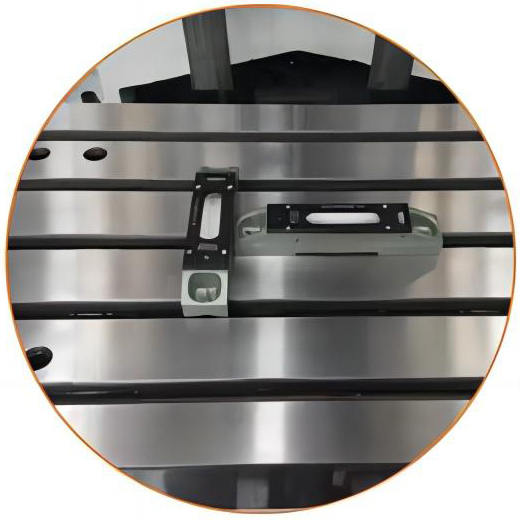

Likarolo tsa Boutique

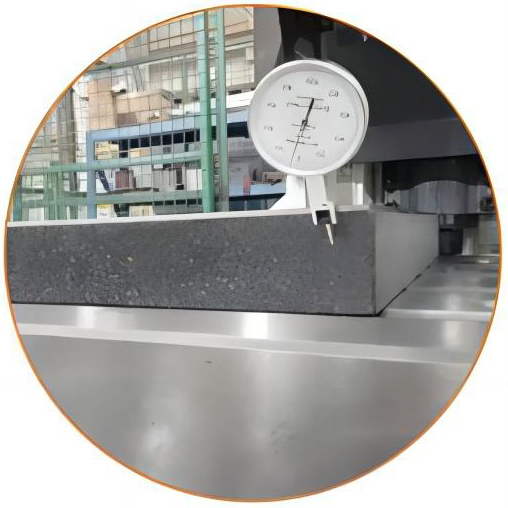

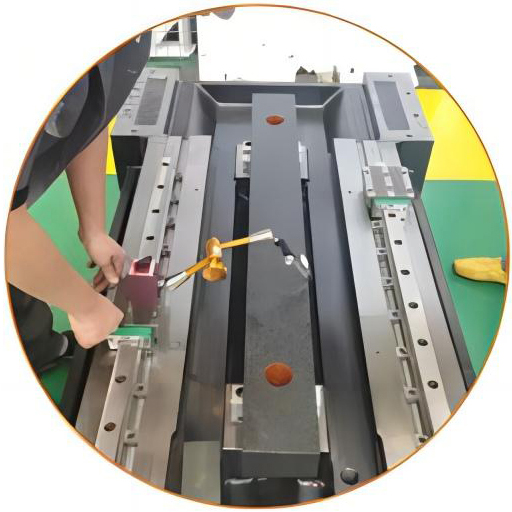

Ts'ebetso ea taolo ea tlhahlobo ea kopano e nepahetseng

Tlhahlobo ea ho nepahala ha Workbench

Tlhahlobo ea Karolo ea Opto-Mechanical

Ho Khetholla Bophahamo

Ho lemoha ha Parallelism

Tlhahlobo ea ho nepahala ha Setulo sa Nut

Ho Khetholla Angle Deviation

Lokisa mofuta oa CNC sistimi

TAJANE Horizontal machining center lisebelisoa tsa mochini, ho latela litlhoko tsa bareki, li fana ka mefuta e fapaneng ea litsamaiso tsa CNC ho fihlela litlhoko tse fapaneng tsa bareki bakeng sa litsi tsa mochini tse otlolohileng, FANUC, SIEMENS, MITSUBISH, SYNTEC.

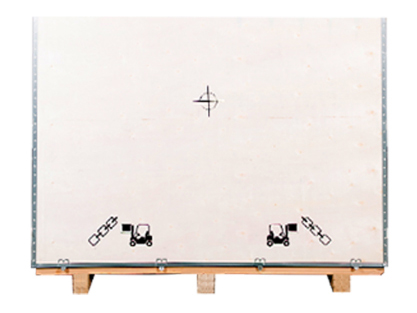

Liphutheloana tse koaletsoeng ka ho feletseng, felehetsa lipalangoang

Sephutheloana sa lehong se koetsoeng ka botlalo

Horizontal Machining Center HMC-1814L, sephutheloana se koetsoeng ka botlalo, se felehelitseng lipalangoang

Sephutheloana sa vacuum ka lebokoseng

Horizontal Machining Center HMC-1814L, e nang le sephutheloana sa vacuum e thibelang mongobo ka har'a lebokose, e loketseng lipalangoang tsa sebaka se selelele.

Letšoao le hlakileng

Horizontal Machining Center HMC-1814L, e nang le matšoao a hlakileng ka har'a lebokose la ho paka, ho kenya le ho laolla litšoantšo, boima ba mohlala le boholo, le kananelo e phahameng.

Bracket e tiileng ea lehong

Horizontal Machining Center HMC-1814L, bokatlase ba lebokose la ho paka bo entsoe ka lehong le thata, le thata ebile le sa thelle, 'me le tiisa ho notlela thepa.

| Litlhaloso | HMC-1814L | |||

| Tsamaea | X-Axis,Y-Axis,Z-Axis | X: 1050, Y: 850, Z: 950mm | ||

| Spindle Nose Ho Pallet | 150-1100 limilimithara | |||

| Setsi sa Spindle To Pallet Surface | 90-940 limilimithara | |||

| Tafole | Boholo ba Tafole | 630x630 limilimithara | ||

| Nomoro ea benche ea mosebetsi | 1(OP:2) | |||

| Sebopeho sa Workbench Surface Configuration | M16-125 limilimithara | |||

| The Workbench Maximum Mojaro | 1200kg | |||

| Yuniti e Nyane ea ho Seta | 1°(OP:0.001°) | |||

| Molaoli le Motor | 0IMF-s | 0IMF-a | 0IMF-s | |

| Spindle Motor | 15/18.5 kW (143.3Nm) | 22/26 kW (140Nm) | 15/18.5 kW (143.3Nm) | |

| X Axis Servo Motor | 3kW(36Nm) | 7kW(30Nm) | 3kW(36Nm) | |

| Y Axis Servo Motor | 3kW(36Nm)BS | 6kW(38Nm)BS | 3kW(36Nm)BS | |

| Z Axis Servo Motor | 3kW(36Nm) | 7kW(30Nm) | 3kW(36Nm) | |

| B Axis Servo Motor | 2.5kW (20Nm) | 3kW (12Nm) | 2.5kW (20Nm) | |

| Fepa Rate | 0IMF-s | 0IMF-a | 0IMF-s | |

| X. Z Axis Rapid Feed Rate | 24m/min | 24m/min | 24m/min | |

| Y Axis Rapid Feed Rate | 24m/min | 24m/min | 24m/min | |

| XY Z Max.Sekhahla sa Fepa se Sehang | 6m/m | 6m/m | 6m/m | |

| ATC | Mofuta oa Arm (Tool to Tool) | 30T (4.5 sec) | ||

| Tool Shank | BT-50 | |||

| Max. Tool Diameter*Bolelele(haufi) | φ200*350mm(φ105*350mm) | |||

| Max. Tool Weight | 15kg | |||

| Ho Nepaha ha Mochini | Positioning Accuracy (JIS) | ± 0.005mm / 300mm | ||

| Pheta Poitioning Accuracy (JIS) | ± 0.003mm | |||

| Ba bang | Boima ba Boima | A: 15500kg / B: 17000kg | ||

| Tekanyo ea Sebaka sa fatše | A: 6000*4600*3800mm B: 6500*4600*3800mm | |||

Lisebelisoa tse tloaelehileng

● ponts'o ea mojaro oa li-spindle le servo motor

● Spindle le servo overload tšireletso

● Ho otla ka thata

● Sekoahelo se sirelelitsoeng ka ho feletseng

● Lebili la letsoho la elektronike

● lisebelisoa tsa mabone

●Mohatlana oa "spiral chip" ea habeli

● Automatic lubrication system

● Thermostat ea lebokose la motlakase

● Spindle sesebelisoa tsidifatso tsamaiso

● RS232 segokanyimmediamentsi sa sebolokigolo

● Lithunya tsa Airsoft

●Spindle taper cleaner

●Lebokose la lisebelisoa

Lisebelisoa tsa boikhethelo

●Sesebediswa sa ho bona rulara ya axis tse tharo

● Sistimi ea ho metha ea mosebetsi

●Sistimi ea ho lekanya lisebelisoa

● Spindle pholileng ka hare

● Tafole ea rotary ea CNC

● Ketane chip conveyor

● Setha bolelele ba sesebelisoa le sebatli sa moeli

●Se arolang metsi

●Sesebediswa sa ho phodisa metsi ka spindle

● Ts'ebetso ea Marang-rang